The Ultimate Guide to Prototype Injection Molding for Metal Fabricators

As a metal fabricator in the modern business landscape, staying ahead of the competition is vital to long-term success. In the realm of manufacturing, innovation is key, and one revolutionary process that has been shaping the industry is prototype injection molding.

Understanding Prototype Injection Molding

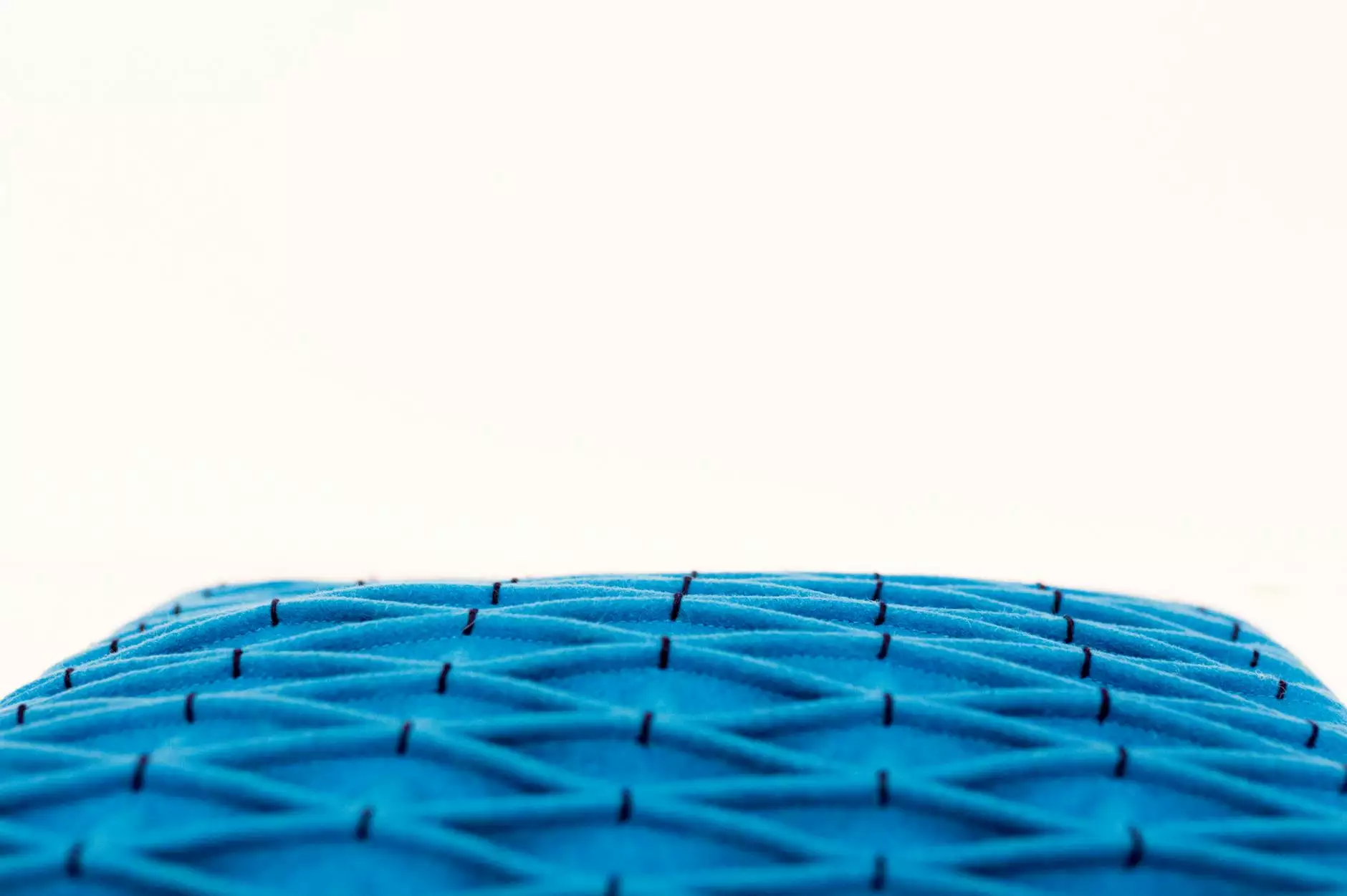

Prototype injection molding is a specialized manufacturing process used to create a prototype or sample of a part before full-scale production. This method allows metal fabricators to test and refine designs quickly and cost-effectively, ultimately leading to higher-quality final products.

The Benefits of Prototype Injection Molding

There are numerous advantages to incorporating prototype injection molding into your metal fabrication process:

- Rapid Prototyping: Prototype injection molding enables fast production of prototypes, reducing time-to-market for new products.

- Cost-Effectiveness: By identifying and rectifying design flaws early in the process, metal fabricators can save significant costs that would have been incurred in full-scale production.

- Enhanced Product Quality: Testing prototypes allows for adjustments to be made to improve the overall quality and functionality of the final product.

- Customization Options: Prototype injection molding offers flexibility in design choices, allowing metal fabricators to experiment with various iterations before committing to mass production.

How DeepMould.net Can Help

At DeepMould.net, we specialize in providing cutting-edge prototype injection molding solutions tailored to the unique needs of metal fabricators. Our team of expert engineers and designers are dedicated to helping businesses thrive in a competitive market through innovative manufacturing processes.

With state-of-the-art technology and a commitment to excellence, DeepMould.net offers:

- Customized Solutions: We work closely with metal fabricators to develop prototypes that meet their specific requirements and exceed their expectations.

- Quality Assurance: Our rigorous quality control measures ensure that each prototype meets the highest standards of precision and durability.

- Timely Delivery: We understand the importance of timelines in the manufacturing industry and strive to deliver prototypes promptly without compromising on quality.

- Ongoing Support: Our relationship with clients extends beyond the prototype stage, providing continued support and guidance throughout the production process.

Conclusion

In conclusion, prototype injection molding is a game-changer for metal fabricators looking to innovate and streamline their production processes. By embracing this cutting-edge technology and partnering with industry leaders like DeepMould.net, businesses can unlock new possibilities for growth and success.